Fun Tips About How To Build A Kiln For Ceramics

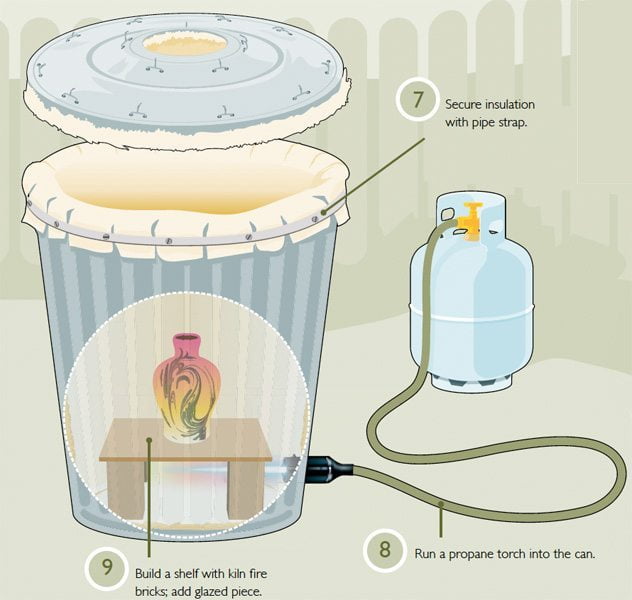

You can also get some temperature regulators to keep an eye on the exact temperature.

How to build a kiln for ceramics. Dig into the ground about the depth of a brick to give the structure a little more stability. I left about an inch, to an inch and a half from the edge and the top of the u so the elements are not too. Step by step guide 1.

Ceramic fibre blanket (such as kaowool) refractory cement; What are the steps for building the kiln? 25 cheap diy kiln ideas to build your own kiln for pottery 1.

Remember to leave a gap in the bricks, carve a hole in the clay, or just drill into the barrel. An old oil drum or metal dustbin with lid. Firstly, make a square hole of a 4 x 4 inch at the base of your can.

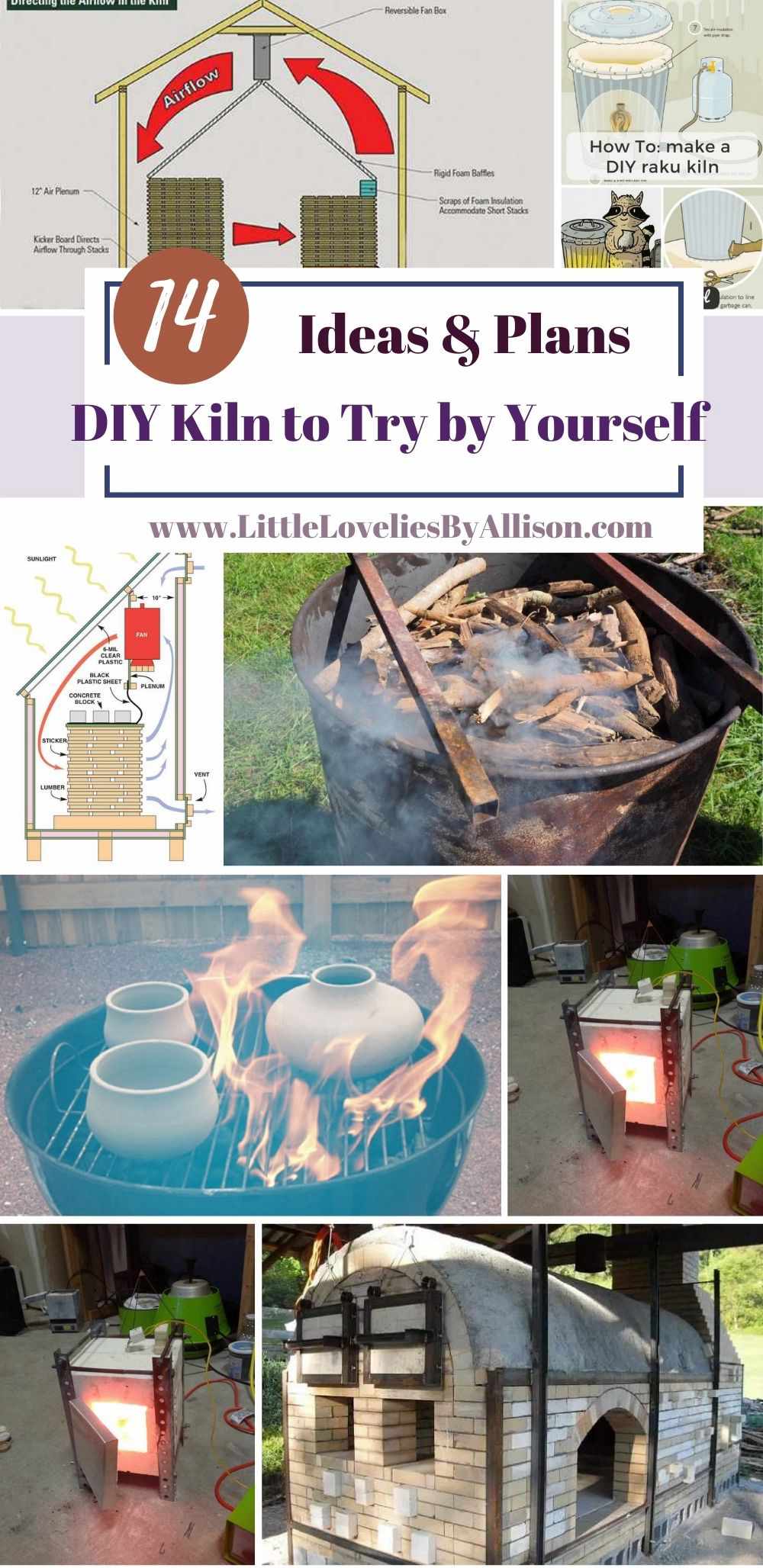

A typical kiln is built from about 50 insulating bricks (ifbs), a square kiln shelf (size depending on what to fire), a metal grill for a grate, a piece of sheet metal, and some. The clay gets an assemblage to build the pottery kiln dug up from the ground of nearby areas, and then the mixture of clay and other elements will be used to make it even. The flame will go from this hole.

A burner from a hardware store (the sort. Start building the kiln’s base by laying bricks on. Burner ports still to be cut in the photo above these come in middle right and bottom.

Load the kiln, starting with your pottery. Put on a dust mask and coat the base of the kiln with sawdust. Students build the walls and begin the stack.